Regarding Lead-Carbon Battery Technology

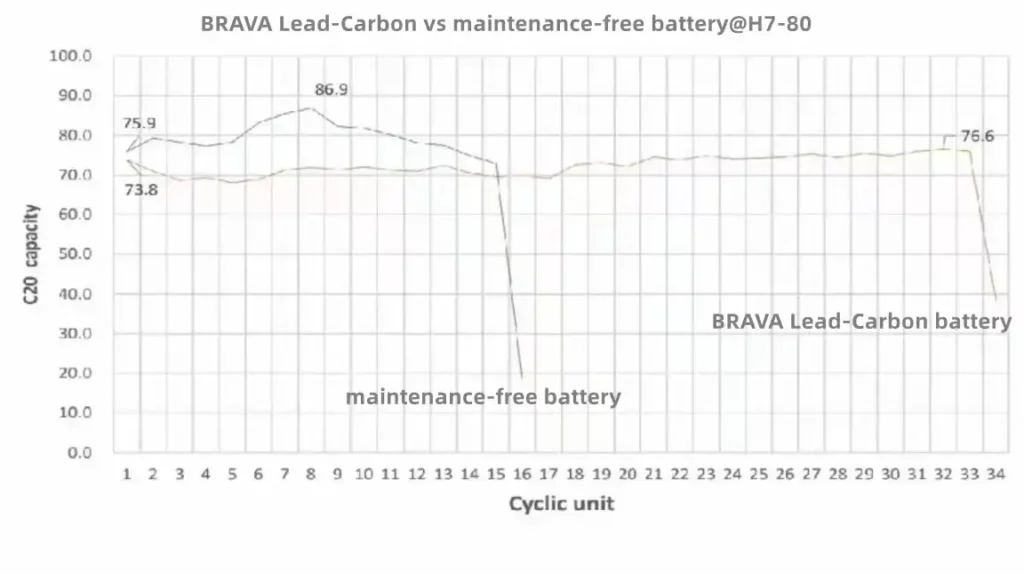

As a global specialist in lead-acid battery grid plate supply, Brava battery began researching Lead-Carbon technology as early as 2013, achieving mass production in 2016. Over the years, through continuous technical accumulation, Lead-Carbon batteries have become a shining point of Brava battery’s product lineup, receiving unanimous praise from numerous customers!

Through years of dedicated research, combined with our advantages in the industry supply chain, we have optimized designs through practical experience, ensuring constant upgrades and innovation in our products. Brava battery’s Lead-Carbon Battery Technology stands at the forefront of the industry, even internationally, and is being widely adopted across the Brava battery product range.

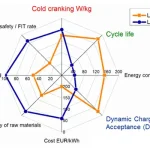

One of the earliest applications of this technology was in Brava battery’s AGM batteries for automotive start-stop systems (Lead-Carbon batteries). This technology plays a crucial role in automotive start-stop systems, enabling Brava battery start-stop batteries to exhibit outstanding performance during operation. Its high instant start-up capability, rapid energy acceptance, and exceptionally long cycle life are among the product’s key technological advantages.

Additionally, Brava battery has developed products with varying performance requirements to cater to the diverse needs of automotive battery customers, making them suitable for a wider range of applications and better serving our customers.

In the future, building upon our existing Lead-Carbon technology, Brava battery will continue to optimize and innovate, aligning more closely with market demands. Our aim is to enable more users to experience the fruits of Brava battery’s technological advancements, and we are committed to contributing to global Lead-Carbon battery technology and the realization of global carbon reduction goals. We pledge our humble efforts in achieving these goals!

Stop-Start AGM Battery Models

| Model | Voltage(V) | CCA(A) | Capacity(Ah) | Dimensions (L,W,H,Total Height*mm) | Weight(kg) | Terminal | mΩ |

| H4/AGM-50 | 12 | 540 | 50 | 207*175*190*190 | 17.5 | M8 | 8.5 |

| H5/AGM-60 | 12 | 600 | 60 | 242*175*190*190 | 19.0 | M8 | 8.0 |

| H6/AGM-70 | 12 | 760 | 70 | 278*175*190*190 | 21.1 | M8 | 7.5 |

| H7/AGM-80 | 12 | 850 | 80 | 315*175*190*190 | 24.5 | M8 | 6.6 |

| H8/AGM-90 | 12 | 900 | 90 | 353*175*190*190 | 27 | M8 | 6.5 |

| H9/AGM-105 | 12 | 950 | 105 | 400*175*190*190 | 29.6 | M8 | 6.0 |

Stop-Start EFB Battery Models

| Model | Voltage(V) | CCA(A) | Capacity(Ah) | Dimensions (L,W,H,Total Height*mm) | Weight(kg) | Terminal | mΩ |

| H4/EFB-50 | 12 | 540 | 50 | 207*175*190*190 | 19.1 | M8 | 8.3 |

| H5/EFB-60 | 12 | 600 | 60 | 242*175*190*190 | 21.1 | M8 | 7.5 |

| H6/EFB-70 | 12 | 760 | 70 | 278*175*190*190 | 22.1 | M8 | 7.3 |

| H7/EFB-80 | 12 | 850 | 80 | 315*175*190*190 | 24.8 | M8 | 6.6 |

| H8/EFB-90 | 12 | 900 | 90 | 353*175*190*190 | 27.2 | M8 | 6.3 |

| H9/EFB-105 | 12 | 950 | 105 | 400*175*190*190 | 30.2 | M8 | 5.8 |

H6

H7

H8

H9

Battery Size Codes

Batteries come in all different sizes. Many have “group” sizes, which is based upon the physical size and terminal placement. It is NOT a measure of battery capacity. Typical BCI codes are group U1, 24, 27, and 31. Industrial batteries are usually designated by a part number such as “FS” for floor sweeper, or “GC” for golf cart. Many batteries follow no particular code, and are just manufacturers part numbers. Other standard size codes are 4D & 8D, large industrial batteries, commonly used in solar electric systems.

Some common battery size codes used are: (ratings are approximate)

| U1 | 34 to 40 Amp hours | 12 volts |

| Group 24 | 70-85 Amp hours | 12 volts |

| Group 27 | 85-105 Amp hours | 12 volts |

| Group 31 | 95-125 Amp hours | 12 volts |

| 4-D | 180-215 Amp hours | 12 volts |

| 8-D | 225-255 Amp hours | 12 volts |

| Golf Cart & T-105 | 180 to 225 Amp hours | 6 volts |

| L-16, L16HC etc. | 340 to 415 Amp hours | 6 volts |