BravaBattery sealed lead-acid battery is shipped charged, handle the battery according to the following instructions before use:

BravaBattery sealed lead-acid battery is shipped charged, handle the battery according to the following instructions before use:

1. Introduction

Brava produces world-class VRLA batteries based on years of research and development. Our products are manufactured under the guidelines of ISO9001 quality system. Each Gel or AGM battery undergoes a series of strict manufacturing and quality control processes before shipment. We are committed to provide our customers the best batteries, with 100% customer satisfaction. We believe that the Bravabattery is the ideal selection for your application and your ultimate DC power choice.

2. Safety precaution and protection equipment

-

- When working any battery system, be sure you have the necessary tools and safety equipment,

including but not limited to:

a) Insulated tools

b) Rubber apron and gloves

c) Face protection/face shield

d) Safety goggles

e) Fire extinguisher

f) Emergency eye wash and shower, if available

g) Acid spill cleanup kit - Pay attention to the electrical warning symbols to avoid serious injury or death caused by

electrical shock or burns. - Remove all rings and jewelry while working on batteries.

- Multi-cell battery systems can attain high voltage and/or currents. Do NOT touch un-insulated

batteries, connectors or terminals. To prevent serious electrical burns and shock, use EXTREME

CAUTION when working with DC Battery system - Always wear safety protection clothes and protect all exposed skin and eye surfaces

- Use non-conductive or insulated tools when working with ANY battery system.

- All installation tools should be adequately covered with vinyl electrical tape or suitable no-conducting

material to minimize the possibility of shorting across connections. - Never lay tools or other conductive objects on the battery.

- Avoid any possible reasons for shorting, explosions and personal injury.

- Do NOT throw away any batteries or battery components, they are recyclable resources

- When working any battery system, be sure you have the necessary tools and safety equipment,

![]()

3. Battery Storage

-

-

-

- High temperature or poor ventilation during storage and delivery will result high self-discharge rate. Therefore, it is important to maintaining good ventilation and keeping away from fire, flame, water and heat supply etc.

- When storing the battery (not charging), disconnect from charger and load.

- Store the batteries in a dry, clean and preferably cool location.

- The batteries are supplied charged, however during storage it is advisable not to store batteries for more than below without a supplementary recharge:

- a) Six months at 20 °C

- b) Three months at 30 °C

- c) Six weeks at 40 °C

- d) Three weeks at 50 °C

- A supplementary charge is required to maintain the batteries stored for some period over advised time limit from above. For detailed charging procedures, please refer to section 6.1 Supplementary Charge. Failure to observe charging conditions may result in greatly reduced capacity and service life.

-

-

4. Batteries Installation Considerations:

- No fire, flame or heat supply should be near the battery;

- Avoid installation near heat supply or in direct sunlight;

- Avoid operating in humid / damp locations;

- Do not operate in sealed enclosed or without ventilation.

| Temperature Range | UL94-HB Standard Jars | UL94-V0 Flame Retardant Jars |

| Charging : | -4°F ~ +140°F (-20°C ~ +60°C) | -4°F ~ +131°F (-20°C ~ +55°C) |

| Discharging : | +32°F ~ +122°F (0°C ~ +50°C) | +32°F ~ 122°F (0°C ~ +50°C) |

| Storage : | -4°F ~ +140°F (-20°C ~ +60°C) | -4°F ~ +131°F (-20°C ~ +55°C) |

| Parallel Connections : | Recommended within 4 groups. | |

| Heat Dispersing : | Maintain 0.4 to .79” (10 to 20mm) inter-bloc distance between batteries. | |

| Multilayer Installation : | Temperature of each layer should be controlled within 3°C. | |

| Ventilation : | Ensure batteries are stored and used in ventilated conditions. | |

| Optimum Ambient Temp. : | 72°F to 78°F (23°C to 26°C) | |

| Float Charge (25°C) : | limited current ≤0.30C10, voltage 2.23~2.30V/cell | |

| Cyclic Charge (25°C) : | limited current ≤0.30C10, voltage 2.30~2.40V/cell | |

| Mixing Batteries : | Do not mix new and old batteries, batteries of different capacity or manufacturers. | |

5. Batteries Installation

5.1 Unpack and check

- Check the packaging for signs of shipping damage.

- Unpack and check the appearance of battery for signs of damage or unidentified fluid.

- Check parts list ensuring all accessories are included.

- Read through the operation guide before handling with the battery.

Handle the battery with cautions:

a) Avoid any impact or force on the battery terminals!

b) Avoid any impact to the battery!

c) Do not tamper with battery seals!

d) Do not place the battery upside down!

e) Do not short circuit the battery!

5.2 Notices before Batteries Installation

- If no shipping abnormity after checking, install the batteries in the designated position;

- When installing batteries in a cabinet or on a rack, start at bottom & finish with placement at the top.

- Do NOT install batteries near any potential heat source such heat exhaust of other equipment;

- Batteries may release flammable gas. Batteries must keep away from any possible source of flames or sparks.

- Before connecting inter-cell connectors, lightly clean post terminals with non-metallic brush to remove any sulfate or dirt from the terminal. Brush gently and do NOT damage the tin plating on terminal, connector, or lugs.

- Avoid any conductive materials touching directly between positive and negative terminals.

- All installation tools must be insulated to prevent accidental arc flash.

- Do NOT lubricate rack rails or bottom of battery jar as some lubricating compounds may cause deterioration of the plastic battery container. Do NOT clean battery jars with detergent, petroleum-based solvents or solutions with any ammonia to clean the battery containers, as these materials may cause permanent damage to the battery container. Physical damage such as these are not covered under warranty

5.3 Pre Installation Rack/Enclosure Location Check

Floor bearing: Since batteries are heavy, check the floor loading is not exceeded. Check rack/enclosure complies with any load spread requirement, and seismic zone requirements of the installation area. To assemble a Brava battery rack/enclosure, see rack installation instructions.

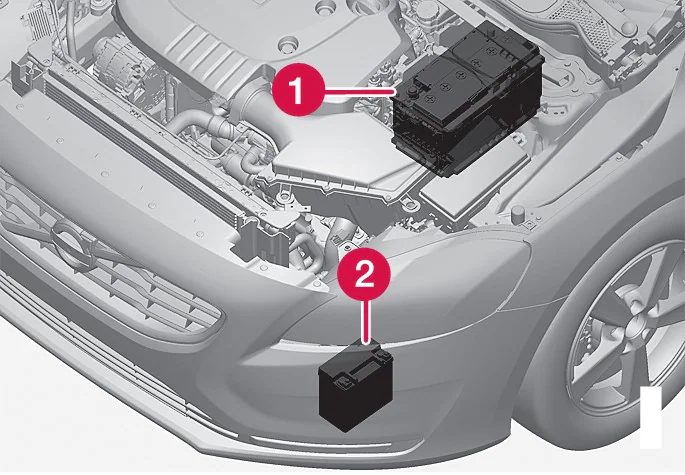

5.4 Batteries Installation and connection

- Use insulated tools only;

- Connect battery modules together to the required system voltage, then connect battery string with charger or load;

- When multi-strings of batteries are to be parallel connected, connect batteries in series first & then complete the parallel connection. Parallel cables to the charge/load should be as close in size and length from each of the parallel strings to prevent uneven voltage drops that can imbalance the parallel battery strings.

- To ensure good ventilation, the batteries per row should keep around 0.4” to .79” (10 – 20mm) inter-bloc spacing;

- A good rule of thumb on the proper cable sizing between batteries:

-

- AWG# 6 for loads up to 90 Amps.

- AWG# 2 for loads up to 150 Amps.

- AWG# 1/0 for loads up to 250 Amps.

- AWG# 4/0 for loads up to 400 Amps.

- Refer to NEC for voltage drops for long cables.

- Before connection, lightly clean the battery terminals to remove sulfate and dirt.

- Before connecting inter-cell connectors apply a light coating of No-Ox grease to the surface of the terminal and inter-cell connectors or cable lugs;

- After batteries are installed, test the voltage of the battery string. Make sure there are no battery modules that have been incorrectly installed in reverse polarity. If all modules installed correctly, link battery to load.

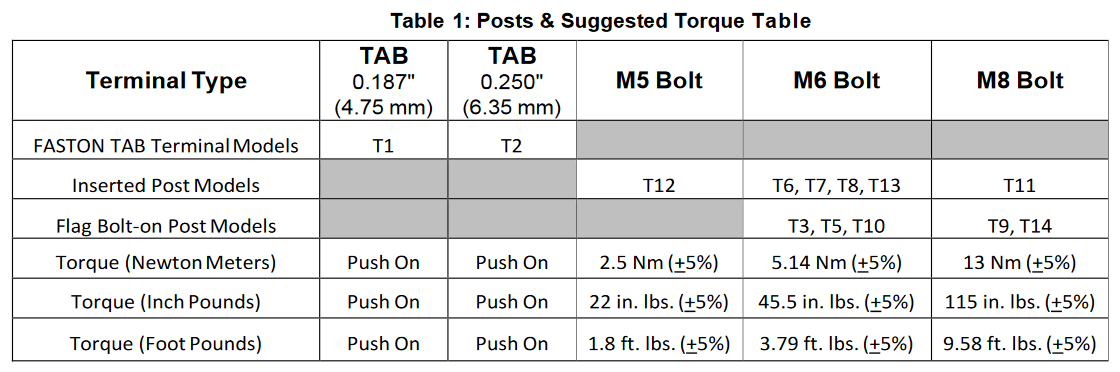

- Use correct torque on all terminals, ensuring every connecting nut and screw is secure; see torque settings as table 1 below.

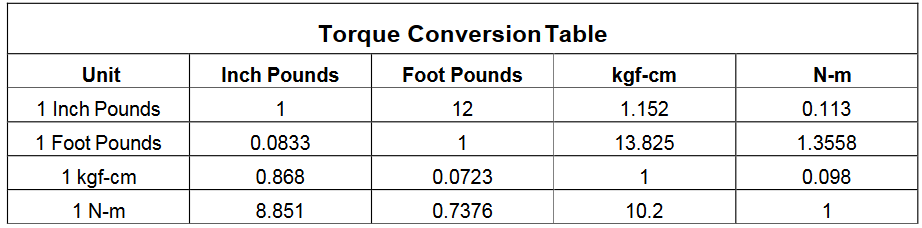

Table 1: Posts & Suggested Torque Table

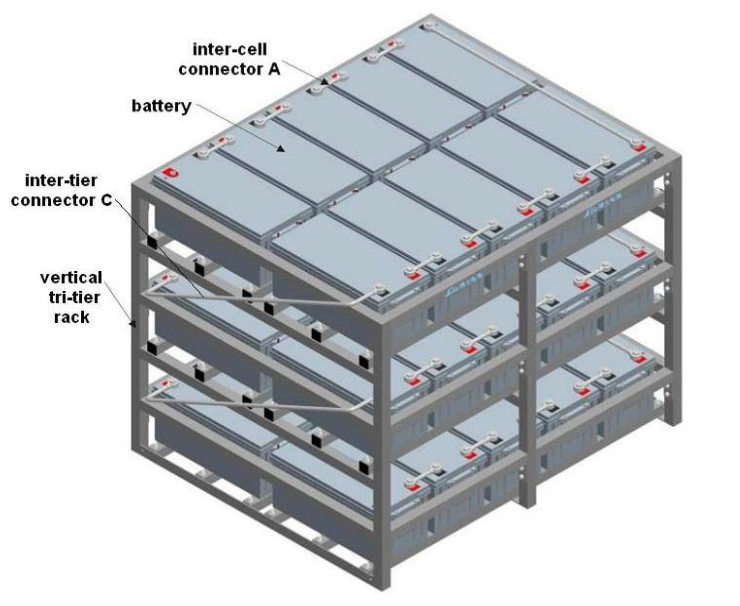

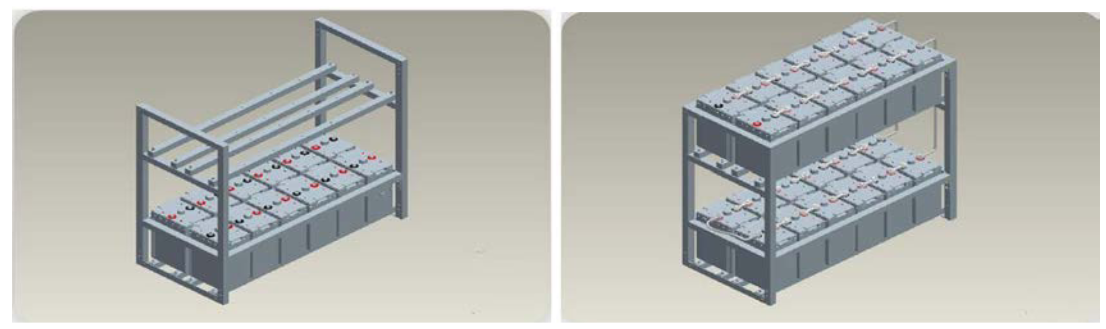

5.5 Battery Rack Assembly

To assemble a Brava battery rack, see rack and/or cabinet enclosure installation instructions.

5.6 Batteries mounting on racks

Rack mounted Brava batteries follow the procedures below: If batteries are small they can easily be lifted into place. If batteries are large special caution should be considered.

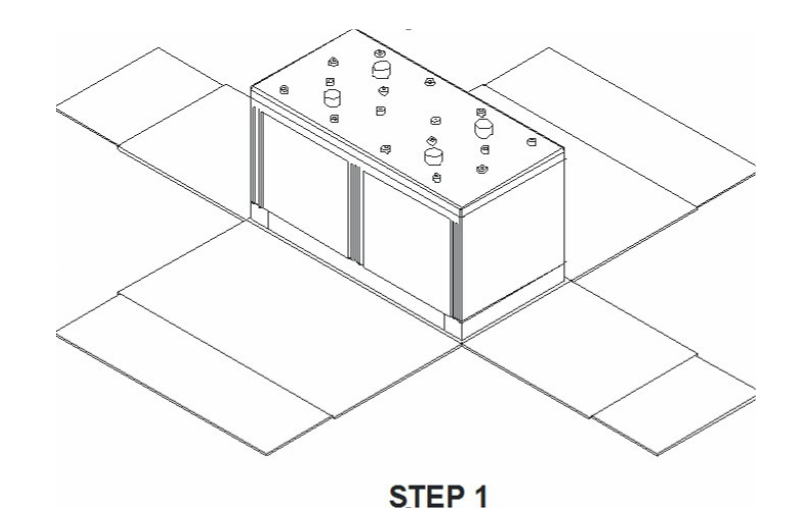

Step 1. Carry batteries close to the rack, and then tear the box along its four corners.

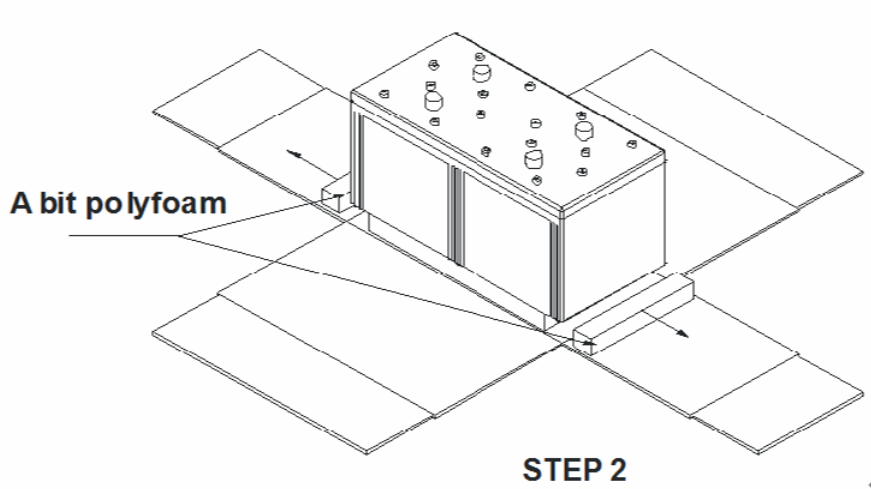

Step 2. Remove all bit poly-foams out from the bottom of the battery.

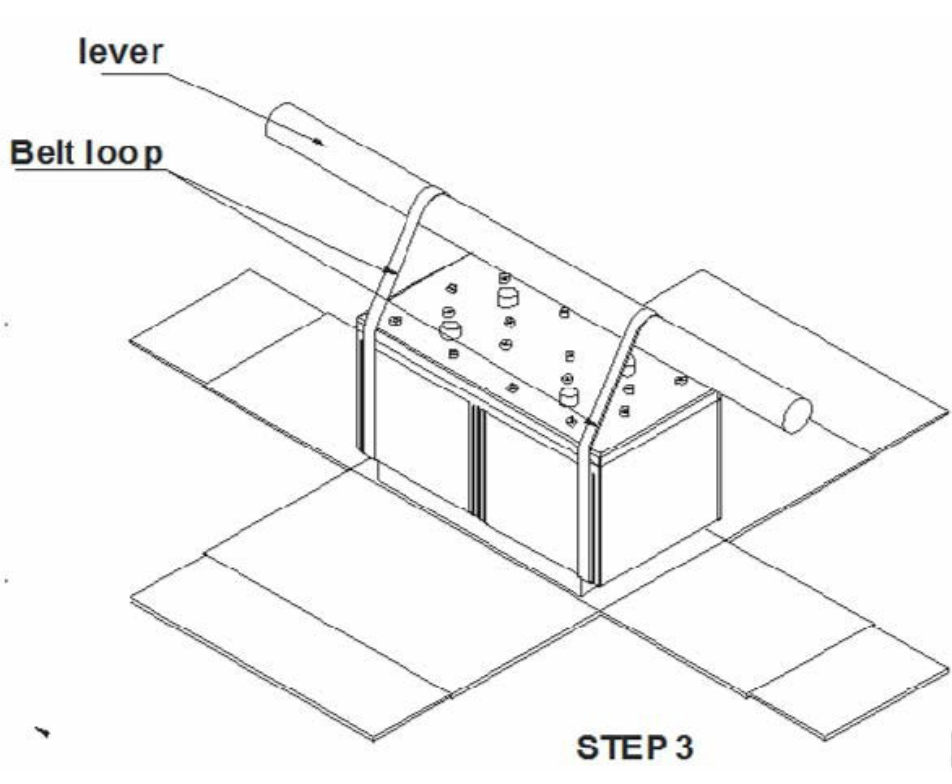

Step 3. Hitch the battery with belt loops from the bit poly-foams, and then let the lever through the belt loop.

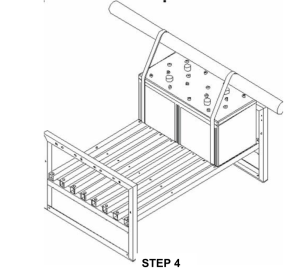

Step 4. Carry the battery up to the top of baffle.

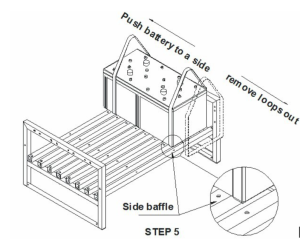

Step 5. Put the battery close to a side for a little gap and remove loops out.

5.7 Example Images after Installation

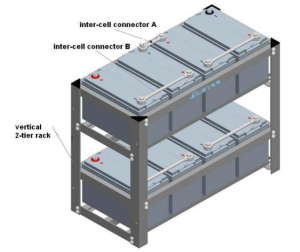

5.7.1 12V Battery Vertical 2-Tier/ 1-Row/Non-seismic Rack (8 batteries shown)

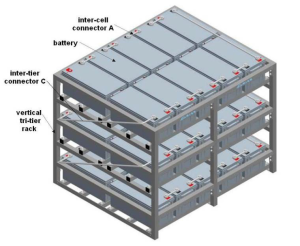

5.7.2 12V Batteries: Vertical 3-tier/ 2-row Rack (30 batteries shown)

6. Operation of battery

6.1 Supplementary charge

- During the delivery and storage, the battery will lose part of the capacity due to self-discharge, so please supplement charge before use;

- If storage occurs before installation / connection, supplement charge regularly; Supplementary charge according table 2 below before use:

Table 2 the time interval of supplementary charge and storage temperature

Note:

Current value C is rated capacity of battery.

Example: rated capacity of 2V300AH battery is 300AH, 0.1C (A) = 0.1X300 = 30A;

6.2 Discharge

- Ensure the maximum allowable discharge current does not exceed the rated value.

- Refer to the individual battery literature for discharge rates to different end VDC at 77⁰F (25⁰C).

6.3 Capacity discharging test

Use the test procedure as identified in IEEE standard 1188.

6.3.1 Before doing any type of discharge test

- Make sure the battery is fully charged with an equalize charge, followed by a battery returning to float for 7 additional days before the test for maximum results. Make sure all of the connections are clean, tight, and do not have high resistance connections. The ambient temperature should be 77°F (25°C) or corrected for temperature as per the IEEE K factor chart.

- Terminal voltage, ambient temperature, and start time should all be checked and recorded before commencing discharge.

- Terminal voltage, discharge current, room temperature should be checked and recorded throughout the discharge period.

- Battery should be recharged soon after the discharge, preferably using a

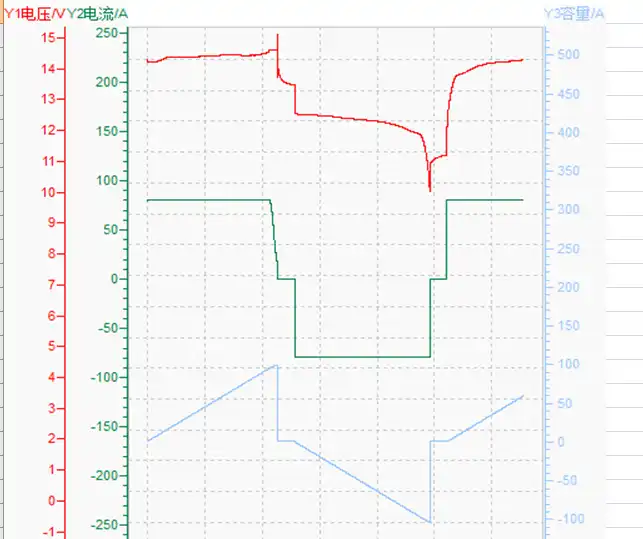

6.4 Charge

6.4.1 Float Charge Parameters:

- Charge voltage: 2.23 ~2.30V/cell at 77°F (25°C)

- The maximum charge current: 0.30C10

- Temperature compensation coefficient: -3mV/cell (taking 77°F (25°C) as base point)

- Total variation range of charge voltage is ±0.02V/cell

Note:

1) All cell/bloc voltages of a battery group have a little difference at the beginning of use, half year later they become matched.

2) Effect from too high float voltage or too low float voltage as below: Too high for a long time (overcharge): life shortened Too low for a long time (not charge enough): Cannot meet load and/or make battery voltages inconsistent. The battery group capacity will drop accordingly and life is shortened.

6.4.2 Cycle Usage Charge Parameters:

- Charge voltage: 2.40 ~2.50V/cell at 77°F (25°C)

- The maximum charge current: 0.30C10

- Temperature compensation coefficient: -5mV/cell (taking 77°F (25°C) as base point)

- Total variation range of charge voltage: ±0.02V/cell

- Charge capacity is 110% ~ 130% of discharge capacity.

6.4.3 Equalization Charge Parameters:

- Charging voltage : 2.35 ~ 2.40V/cell (25°C)

- Maximal charging current : 0.30C 10

- Temperature equalization parameter : -3mV/cell(25°C)

- Variation scope of charging voltage : ±0.02V/cell

Note:

Do not use equalization charging as the standard floating application. Adopt equalization charging under situations below:

- Discharging capacity is below 80% of rated capacity.

- Batteries hasn’t been used for more than 3 months.

- Float voltage of battery unit is less than 2.18V/cell

- Batteries have been floating for 3 ~ 6 months and found low voltage batteries in the string.

- Batteries have been floating for a year.

- Batteries supplementary charged before used.

- After performing a capacity test.

6.4.4 Notes during charging

- Charge current at the end of charge is over 0.05 C10A, which may result in permanent damage on battery appearance and battery life; pay more attention to charging voltage.

- The used charger should have digressive automatic constant voltage device, please contact us if use other kind of charger.

- If the ambient temperature is not 25°C, temperature compensation should be applied on the voltage, using the formula is U=U25°C – K×(T -25)

- T-ambient temperature; K—temperature compensation coefficient

- Judgment on charge end point, usually, if the battery charge can meet any one of the below listed condition, it can be regarded as the charge end point.

-

- Charged value is not less than 1.2 times of the released value.

- The current is less than 0.005C10A (C10 = rated capacity of the battery) during the final period of charging.

- The current is steady for 5 hours during the final period of charging.

7 Battery maintenance

7.1 Cleanness

- Keep the battery surface and its working circumstance clean and dry.

- Keep battery clean and avoid static condition.

- Clean battery with damp cloth with water in it, avoiding contact with terminals. No organic solvent such as gasoline, alcohol, etc. or clothes with such substance should be used to clean battery. Use of unapproved cleaning solvents may permanently damage the battery container and is not covered by battery warranty.

7.2 Inspection and maintenance

To better understand the operation of battery and equipment and also to prevent battery damage during maintenance inspection, please periodically inspect the battery and record it

7.2.1 Inspection items per month:

| Items | Contents | Standards | Maintenance |

| Total float charging voltage of battery group | Measure output end voltage of positive and negative end of battery group with voltage meter. | 1. tested data comply with the data displayed on the meter and meet the voltage standard under the temperature conditions 2. The error of float charge voltage after temperature compensation Is ≤±50mV |

1. If data attained by testing is varies from the standard, the tested data should prevail. 2. For those adjusted by monitor module and still can’t reach the allowed error range after module adjustment, repair is to be applied or send them back to factory. |

| Battery appearance | Inspect battery case and cover for bulge, leakage or damage. | Normal | Find out the reasons if abnormal appearance exist, please change battery if it effects the normal use of battery group |

| Inspect for dust or stains | Clean | Clean the dust and stain with damp cloth. | |

| Inspect the harness and terminal for rust or corrosion. | No rust | Clean the rust, change the harness and paste with antirust coating/paste. | |

| Temperature of the battery | Test the temperature of the terminal and battery surface by infrared thermometer | Under 35 °C | Determine reason for temperature being above standard value and proceed on relevant course of action. |

| Connection Parts | Check the tightness of terminal bolt/screw with torque spanner | Fastness please refer to the table of torque | Tighten the loosen bolt/screw in time |

| Check the connection cable and terminals for dirt and corrosion | Without appearance of corrosion or dirt | Take out the connection cable and clear it in water if it is light corrosion, for serious corrosion please replace the cable and clear the connection point with a steel brush before attaching new connectors | |

| Check Safety Valves (2V series) | Shake the valve lightly to check the valve is fixed tightly. | Valve is fixed tightly. | Please tighten the value if there is appearance of looseness |

| Cover the valve with bubble liquid(soap solution) to check if the valve can exhaust gas cleanly | Staggered air bubble appears | The frequent tighten the valve if there is appearance of open and close the value is abnormal, in case happens, please replace the valve at the same time, please check the water lost status of the battery. | |

| Switch DC power supply | Cut off AC power supply and change to UPS or DC power supply | AC power supply switch to UPS or DC power supply smoothly | Correct the potential difference

|

7.2.2 Inspection items per quarter

Apart from the maintenance per month, additional articles added as below:

| Items | Contents | Standards | Maintenance |

| Float voltage of each battery | Measure the end voltage of each battery in battery group. | Float voltage value after temperature equalization ±50mV | If float voltage is over standard value, please apply equalization charge the battery group after discharging them and then float charge them for 1 ~ 2 month, please contact us if still have any deviation from standard. |

| Repair batteries which with laggard single cell | 1. Equalization charge of the battery group: charge the battery at upper limit voltage and last more than 10H, 3 times of discharge cycle is necessary when case is serious. | The difference of float charge voltage between single cell in a group of battery should meet the below standard: 2V series 90mv, 6V series 240mv , 12V series 480mv |

Single cell should be replaced if it fails in repair. |

| 2. On-line repair of single cell: connect the cell the activation meter or charger with the laggard battery and charge the single cell. | |||

| Activation charge and discharge | Charge and discharge the battery by one cycle, then charge the battery by the lower limit of the equalization voltage |

About 30% of the rated capacity is released. |

Produced this text on the batteries which float charge more than 6moths but without discharge. |

7.2.3 Inspection item per year

Apart from the maintenance per quarter, additional articles added as below:

| Items | Contents | Standards | Maintenance |

| Checking discharge test |

Cut off AC power supply, discharge battery with load, and discharging 30% ~ 40% rated capacity. | Battery voltage should be over 1.90V/cell after discharging. | If battery voltage is lower than standard value, please equalization charge the battery group after discharging and then float charging it for 1~2 month, please contact us if still have any departure. |

| Capacity test | Adopt the on-system capacity test instrument or fake load discharge battery and discharge 60~80% |

More than 80% of the capacity is reserved. | Take down the parameters during the discharging test, if any laggard battery is found, please proceed to relevant operation. |

7.2.4 Basic requirements and cautions on maintenance Requirements:

- Principle “find out the hidden trouble and insure the safety” Should be complied when make test

on the battery. - Daily maintenance and performance analysis should be carried out strictly according the

processing plan. - Battery parameter setting operation should be strictly complied with the maintenance rules and

related requirement. - Always wear insulated gloves when handling the batteries to avoid electric shock. Make sure the

metal instrument is insulated. - Use instrument and meters which meet the test requirement.

- Physical articles:

- Check whether the post and connection is clean or not, whether there is any appearance of

oxidation or corrosion. In case it is serious, please clear it and reduce the resistance. - Check for any loose connection, if any, please tighten them up.

- Check if there is any appearance of acid climbing, leakage of liquid, and whether there is

liquid overflow around the safety valve. - Check if there is any damage, leakage and distortion on the battery case and the post; it

should be without any damage and distortion. - Check there is any abnormal temperature increase on the battery and its connection.

- Check whether the post and connection is clean or not, whether there is any appearance of

- Check and adjust the set of related parameters.

- Check the float voltage, equalization voltage, float charging current is normal or not on the

base of technical parameters and site environment. Please handle it in time. - Check the limited charge current set is correct, please adjust immediately.

- Check the alarm voltage (below voltage and over voltage alarm) of the battery set is correct,

if not, please adjust promptly. - If there is off-load set, please check the off-load voltage is correct, if not, please adjust

CAUTIONS

- Keep batteries out of reach of children.

- Do NOT use batteries for application other than those specified in its specification.

- Do NOT attempt to dis-assemble revised, damaged, impacted, disposed batteries, otherwise

the battery would leak, get hot, or explode. - Do NOT dispose of the batteries in water, fire, and do not heat the batteries.

- Do NOT cause any short circuit

- If the voltage of battery pack is above 45V, please be sure to wear insulated gloves when

working; otherwise, there is a risk of severe electrical shock. - Do NOT bring face close to the top of batteries, please keep a sensible distance when you are

measuring and repairing, you must wear safety goggles. - There is sulfuric acid in the battery, do not allow contact of sulfuric acid with skin, cloths,

especially eyes. If eyes come in contact with sulfuric acid, please wash with a lot of clean

water, and consult a physician immediately. - Longer service life will be attained when the battery is operated within an ambient temperature

range of 20~30°C

8. Exchange of Batteries

8.1 Exchange judgments:

The batteries are discharged 80% (refer the corresponding discharge rates, such as C10, C2 etc.) of rated capacity, at the same time, the voltage is below 1.8V/cell (the discharge rate for 1 hour is 1.7V/cell). It should be exchanged.

8.2 Exchange time

The VRLA battery has the certain service life; please replace the old battery with the new one before the end of service life so that the application can run safely and normally.

9. Maintenance Records

Good records will assist in determining if corrective action is needed to correct charging, maintenance, or environmental issues that may reduce the maximum life of your battery. If you have any questions or concerns, please call Brava Battery for assistance.

Reads are suggested after the battery is installed, and after the battery has been in float service for 6 months (Base Line Readings for warranty records). Quarterly, or semi-annual maintenance records are suggested to give customer system protection predictability, however annual maintenance readings are the minimum to maintain the warranty coverage.

Maintenance records will be required for warranty.

Below please find some suggested maintenance sheets to assist the customer’s record keeping on the battery.

Installation Report

REPORT DATE: _________________

PAGE # _______of________

COMPANY NAME: ____________________________________________

NO. OF CELLS IN STRING: __________________________________________________

CONTACT NAME: _____________________________________________

TYPE OF BATTERY: ________________________________________________________

PHONE: _____________________________________________________

STRING NO.: ______________________________________________________________

BATTERY STRING NAME: ______________________________________

INSTALLATION DATE: ______________________________________________________

BATTERY ADDRESS: ________________________________________________________

AMBIENT ROOM TEMPERATURE: ________________________________

CHARGER IMPOSED AC RIPPLE CURRENT AND OR VOLTAGE: ____________________

CHARGER OUTPUT VOLTAGE: ___________________________________

SYSTEM FLOAT VOLTAGE

CHARGER OUTPUT CURRENT: ___________________________________

AT BATTERY TERMINALS: ___________________________________________________

CHARGER IMPOSED AC RIPPLE CURRENT AND OR VOLTAGE: _________________________

VRLA Batteries Installation & Operation Guide pdf download

Gel Batteries Related Products:

Related Products Application:

Related Gel Batteries Posts:

Tag in this article: #GEL Battery

Tips: more detail information, for gel batteries.