What is grade A battery cell?

As Grade A cell, That’s The battery factory arranges production according to the production capacity and technical capacity of the factory. After a series of battery manufacturing processes, the final product is delivered to the customer; After mass production of battery cells with the same specifications, it is necessary to measure the cells’ rated capacity and internal resistance through a series of testing procedures. And the rated capacity of the cell reaches A predetermined value, the internal resistance is lower than the specified value, and the appearance, performance, and other qualified cell is called A Grade cell.

What is B grade battery cell?

Any factory producing products must have a defect rate. Then this defect rate determines the vitality of a factory. There will not be a big gap between the first-line lithium battery and the third-line lithium battery factory in the lithium industry, purely technology, ingredients, etc. Still, the gap between the defect rate is enormous; the first-tier manufacturers can achieve about 2%. In comparison, the second and third-tier manufacturers are likely to achieve 5-10%. It is precisely because of this defect rate that grade B cell is created. The grade B battery in rated capacity, internal resistance, appearance, or performance and Grade A cell has a certain gap.

All lithium LiFePO4 battery cells like CATL Battery, CALB Battery, Brava LiFePO4 Battery evlithium provides are brand new A grade LiFePO4 battery cells that guarantee stability and battery consistency.

Performance of A Grade vs. B Grade cells

Capacity Fade/Cycle Life – The cycle life of a lithium-ion cell is defined as the number of charge-discharge cycles at 80% Depth of Discharge (DoD) till the retention capacity of the cell comes down to 80% of its original capacity. If the capacity fade of a cell is higher, it tends to have a lower cycle life. B grade cells have a higher rate of capacity fade as compared to A grade cells.

Life – Lithium-ion cells are known for their long-lasting life. The cells degrade and their energy holding capacity reduces over time but they last for a long time, unlike Lead Acid batteries which experience sudden death. B grade cells tend to experience sudden death failure after a certain number of cycles, especially when they are charged and discharged at higher C rates. This does not allow the B grade cells to be reused as second-life batteries and they directly end up at a recycling plant.

Rise in Impedance – Impedance, also known as internal resistance, has an inverse relationship with cell performance. The lower the impedance, the better rate of charge and discharge the cells can go through. EVs demand fast charging and high power discharge, and hence EV Grade cells have lower impedance when compared to Energy Storage Grade cells.

As the cells are charged and discharged, their impedance increases. At some point, the impedance of the cell rises to a level that it becomes unusable for a particular application (such as EVs). At that point, it is disassembled and used as a part of a second-life battery to power applications (such as Energy Storage Systems) using a lower charge-discharge C rating. B grade cells experience a faster rise in the impedance level, and hence they become unusable much earlier compared to A grade cells.

Bulging/Swelling – Bulging of prismatic cells and swelling of pouch cells tend to happen in even A grade cells when they are overcharged, deep discharged or operated at very high temperatures. But the chances of bulging and swelling are higher in B grade cells because their cathode and anode stoichiometric ratio could be off and also due to B grade cells not undergoing proper formation in the first place.

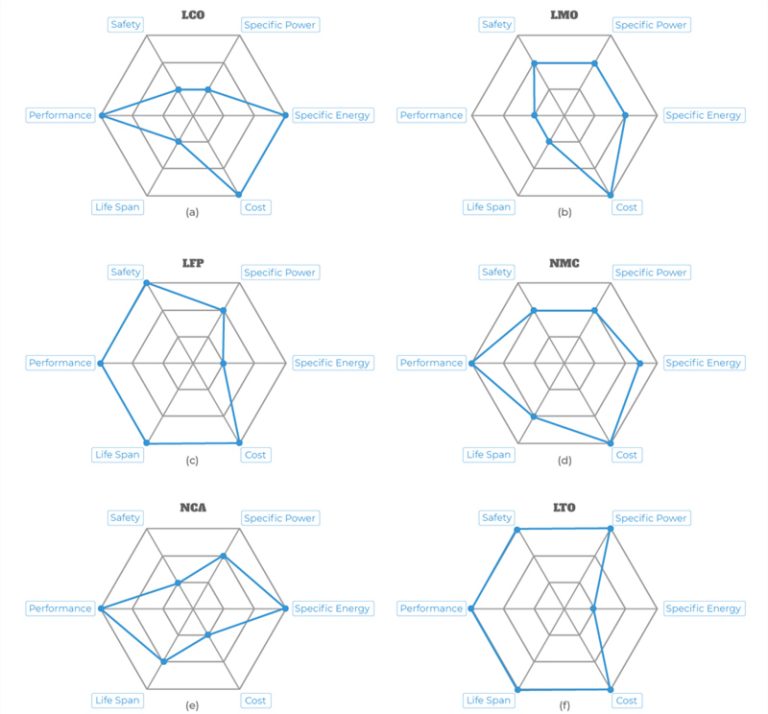

Safety – Since B grade cells do not meet the performance parameters compared to A grade cells, it is not advisable to use B grade cells for fast charging and high power discharge applications such as EVs.

If B grade cells are made to perform at the level of A grade cells, especially in EV applications and combined with a mediocre BMS, consider it a recipe for disaster. It can cause internal cell short circuits due to dendrite formation and lead to thermal runaway. Thermal runaway from NMC chemistry cells can be extremely dangerous as NMC cells tend to catch intense fire, as seen in the cases reported from EV fires from across the globe.

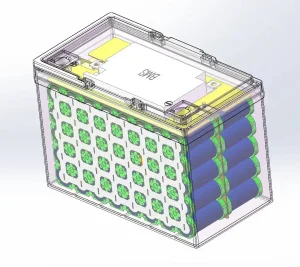

How Do Manufacturers Use Cell Grades In The Manufacturing Of Batteries?

For example, Li-ion cell 053450, some companies may categorize the cell as follows

Grade A— capacity above 1000mAh, internal resistance below 60mΩ

Grade B—capacity 900 to 1000mAh, internal resistance 60mΩ to 80mΩ

Grade C—capacity below 900mAh, internal resistance above 80mΩ

But for some companies with better production lines and capability, they may have higher capacity cells so they may categorize cell 053450 as follows:

Grade A— capacity above 1100mAh, internal resistance below 60mΩ

Grade B—capacity 1000 to 1100mAh, internal resistance 60mΩ to 80mΩ

Grade C—capacity below 1000mAh, internal resistance above 80mΩ

One generally accepted conclusion can be drawn from these two examples and that is grade A cells have the longest runtime and cycle life, grade B has the second longest runtime and cycle life and grade C has the third longest runtime and cycle life.

How To Distinguish Grade A And Grade B Cell – Prismatic Cell

The best way to know a cell is Grade A or Grade B is to check if the cell meets the manufacturers’ specifications. This article will introduce some important specifications on a datasheet. By comparing those specifications with the testing data. We’ll know the differences between Grade A and Grade B cells.

Dimension&Weight

As dimension&weight will be slightly different at different SOC percentage, it would be necessary for you to confirm with the supplier of their testing SOC percentage. Then measure the size at the same SOC percentage level. And compare the measured value with the one they offered on the datasheet.

Internal Resistance

Firstly, confirm the testing environment with suppliers. Including temperature and SOC conditions.AC internal resistance is usually tested at the frequency of 1000HZ. An AC internal resistance meter will help you with the testing. For other manufacturers, they will provide DC internal resistance. Then you may need a multimeter. Compare the real tested data with the one offered in specifications.

Capacity

Capacity is usually tested at the temperature of 25℃, charging and discharging rate of 1C. Record the real tested capacity. And compare these two data.

will send you the cell with its capacity a little bit higher than it should be. If your testing capacity is a little bit higher than the datasheet. If only there aren’t too many differences. That will be alright.

Appearance

The first thing we can do to check a cell is to check its appearance. Each cell was produced with a unique QR code as a proof of identity. Which also makes it more convenient for the manufacturers to offer after-sale services. And as we mentioned in the last post, Grade B cells are categorized as unqualified ones, they usually do not offer a warranty. That’s why they will scrape off this QR code.So if you find a battery cell with QR code concealed. Mostly it is Grade B battery cell. However, all Grade B cells will be covered with a new insulated sheet. So if there are no obvious signs of QR code outside, you’ll need to tear off the insulated sheet.

Capacity Recovery

To test the capacity recovery rate, you just do a 100% DOD charging and discharging cycle. And

check if the capacity recovery rate meets the datasheet.

For example, for a 3.2v 100ah battery cell, if the recovery rate is 95%. We have tested the capacity

at the beginning. It is 100ah. Then after all the tests, we do a 100% DOD charging and discharging.

Then the capacity should be more than 95ah. If yes, the battery capacity recovery rate meets the

datasheet. It’s Grade A quality cell.

Self-Discharge Rate

The self-discharge rate differs at different SOC state. For example, the voltage decrease quicker at 100% SOC than at 50% SOC. So before testing the self-discharge rate, check the battery specification about the testing SOC state first.

During the manufacturing of Lithium-ion cells, a very strict procedure is followed for grading them.Since no manufacturing process can produce 100% perfect yield, less than 10% of the produced cells do not meet the standards required to fall under A grade and hence they are classified as B grade cells. The reasons for rejection can be either the cells do not match up to the expected performance or a cosmetic defect or both. B grade cells also have a minimum performance expectation and if they don’t meet it, they are further classified as C grade cells. C grade cells are the lowest priced cells in the market and they can be used for single-cell portable applications operating at a very slow charge and slow discharge rate with lower expected battery life.

Key points to distinguish of grade A and grade B

| Item | Grade A | Grade B |

| Appearance | With QR code | Generally, the QR code is removed. It is possible to with QR code depending on management of battery manufactures. |

| Testing report | Have a sorting process according to internal resistance, voltage and capacity, this can ensure high consistency on group level and total batch level. | Generally, without sorting process, without battery parameters data. The batteries’ consistency is not good even very bad in one batch. |

| Warranty | Battery manufacturers

will offer warranty |

Battery manufacturer

will not offer warranty |

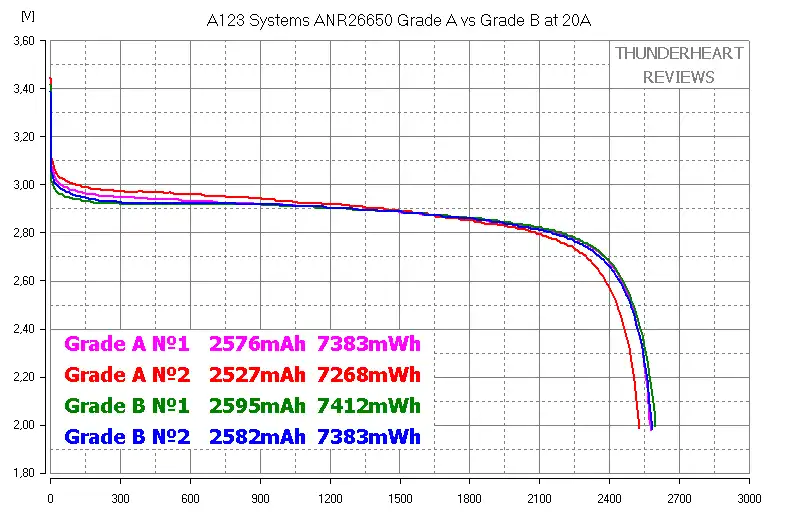

LiFePO4: A123 Systems ANR26650M1B Grade A Vs Grade B – Discharge Capacity Test

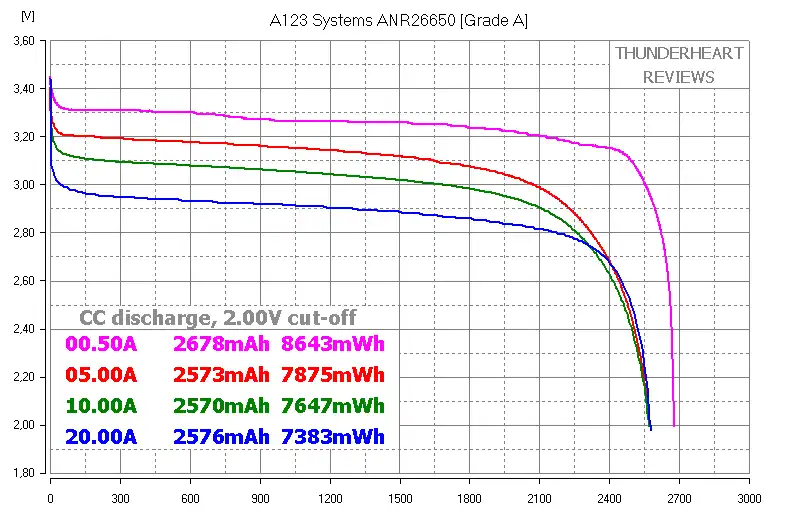

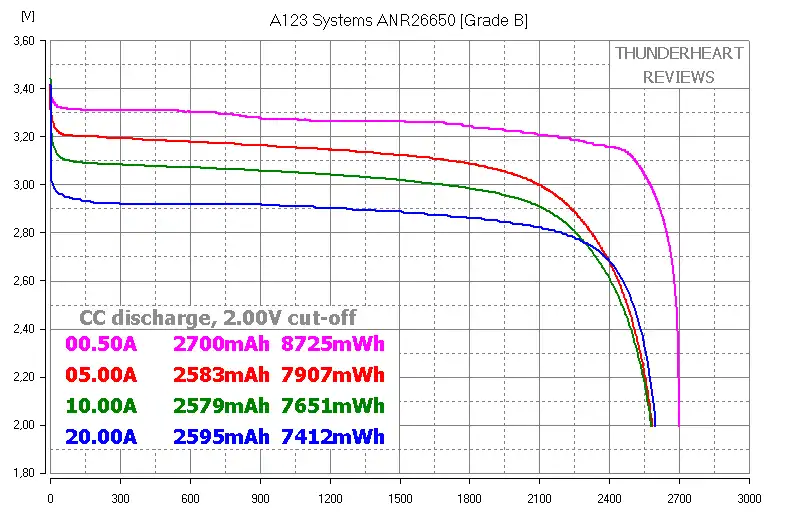

B-class cells are not necessarily lower than A-class cells, we explain through actual measurement, I have got 4 ANR26650 M1Bs – 2 of each grade and tested a pair by discharging at 0.5A (0.2C), 5A, 10A and 20A discharge rates. Then i tested the second pair at 20A and compared all 4 cells.

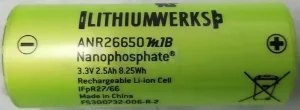

Note: ANR26650M1B cells now are being manufactured and sold under Lithium Werks brand. In March 2018 Lithium Werks acquired A123 Systems’ industrial business and manufacturing plants located in Changzhou, China. These plants were the first to introduce the revolutionary NanoPhosphate® technology in the form of cylindrical cells.

The cells were bought from Queen Battery. The first pair was bought 4 months ago and the second – a month ago.

As always, I’ve tested with ZKETECH EBC-A20 and a self-made battery holder. It’s a PC-connected battery tester supporting 4-wire measuring and discharging at up to 20A.

I’ve followed all the prescriptions of the IEC61960-2003 standard concerning battery’s capacity measurement. Before each discharging cycle each battery was charged at standard current (2.5A) mentioned in the ANR26650M1B datasheet (pdf) to 3.6V (cut-off at 0.1A, which is the lowest supported by EBC-A20). Before each discharging or charging i’ve held a 1-1.5hrs pause. The environment temperature was 20-25°C (23-25°C to be honest).

A123 Systems ANR26650M1B has the following specs according to it’s datasheet:

Nominal capacity: 2.5Ah at 0.5C rate

Minimum capacity: 2.4Ah at 0.5C rate

Nominal voltage: 3.3V

Charge end voltage: 3.6V

Standard charge current: 2.5A (1C)

Fast charge current: 10A (4C)

Max continuous discharge current: 50A (20C)

Max pulse discharge current (10 sec): 120A (48C)

Discharge cut-off voltage: 2.0V

AC impedance at 1KHz: 6mΩ

Weight: 76g

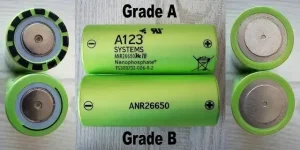

The Grade A cell has more information on its wrapper than the Grade B one which only is marked “ANR26650”

and the Grade B’s negative pole has no stripes around the metal

The positive poles are identical

A123 Systems ANR26650M1B Grade A capacity test results:

A123 Systems ANR26650M1B Grade B capacity test results:

Surprisingly enough, the Grade B cell appears to be slightly better than the Grade A one. So let’s compare 2 Grade A cells with 2 Grade Bs at 20A to see if that’s a rule or exception

It seems that both of Grade Bs are better than the more expensive Grade As. Two pairs are not enough to conclude a rule, but at least we can see that the Bs are not worse than As, if not better. Maybe they have reduced cycle life or they are worse at higher discharge rates or some of them have scratches on the barrel – i don’t know.

A Guide to Understanding Battery Specifications