LEAD CARBON BATTERY TECHNOLOGY

With the progress of society, the requirements for battery energy storage in various social occasions continue to increase. In the past few decades, many battery technologies have made great progress, and the development of lead-acid batteries has also encountered many opportunities and challenges. In this context, scientists and engineers worked together to add carbon to the negative active material of lead-acid batteries, and the lead-carbon battery, an upgraded version of lead-acid batteries, was born.

Lead Carbon Battery Advantages

Carbon enhanced lead acid battery is a kind of lead-acid battery, which is made by adding carbon materials to the negative electrode of lead-acid batteries. Carbon is a very magical element with the most abundant types of compounds. Its addition greatly improves the charge and discharge performance while retaining the original power density of lead-acid batteries. At the same time, carbon lead-acid battery has high safety and reliability, which can make up for the deficiencies of ordinary carbon lead-acid battery that cannot cope with various complex working conditions.

The carbon particles we add to the lead negative electrode will form a conductive network structure, which is used under energy storage conditions. The charge-discharge cycle service life of advanced lead-carbon batteries can reach several times that of lead-acid batteries. In terms of environmental protection, carbon lead-acid battery are environmentally friendly and can achieve 100% battery recycling. The main advantages of this network structure are as follows:

- Provide reaction centers: new reactive centers are formed on the surface of these carbon particles;

- Form a conductive network to reduce polarization;

- Form a smaller and uniform mass transfer network to promote the uniform progress of the electrochemical reaction on the surface and inside of the electrode, thereby reducing the concentrated precipitation effect of PbSO4 on the surface;

- As a heterogeneous material, it hinders the growth of PbSO4 particles and makes them evenly distributed.

- Improve the capacity and power characteristics of the battery through the capacitive effect of carbon.

Based on the above network structure, the lead-carbon battery advantages are to effectively suppress the sulfation trend of the negative electrode, which significantly improves the battery service life. Not only that, the production process of lead-carbon batteries has no essential difference compared with traditional lead-acid batteries. Thus, there is no need to change the now mature process, and it is easy to achieve scale production, especially for the long-life and low-cost requirements of energy storage batteries.

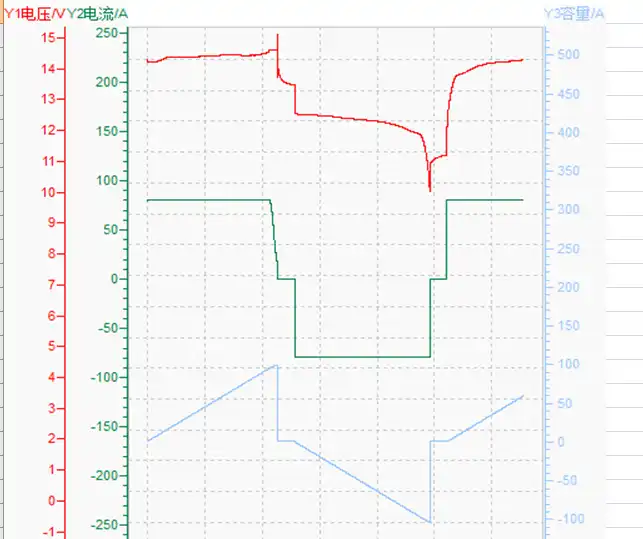

Moreover, carbon itself has good electrical conductivity and capacitance characteristics, so lead-carbon battery has better low-temperature start-up capabilities, charge acceptance capabilities, and high-current charge-discharge performance than traditional lead-acid batteries. When working with high current: The capacitive carbon material plays a “buffer” role. When the lead-carbon battery is charged and discharged with frequent instantaneous high-current, the current is mainly released or received by the carbon material with capacitive characteristics. At this time, the impact of the large current received by the lead metal negative electrode is small, so it is not like the traditional lead acid batteries, “negative sulfation” occurs rapidly under high current, which effectively prolongs the service life of the battery; when working at low current: It is mainly worked by the negative electrode of the sponge lead to continuously provide energy. The energy stored in the carbon by the capacitance energy due to the impact of the large current will also react with the nearby lead, and the reaction is gradually homogenized.

For lead-carbon batteries for sale, there are many types of added carbon: carbon black, activated carbon, graphene, graphite, carbon fiber, and carbon nanotubes. The main functions they can provide for lead-carbon batteries are electrical and thermal conductivity; network pore structure, providing specific surface area required for the reaction, and electric double-layer capacitance. It can be said that the development of lead-carbon battery technology has given carbon materials a stage to display their talents.

Lead-carbon Supercapacitor Battery

Lead-carbon battery is a new type of super battery that combines lead-acid batteries and supercapacitors: it not only takes advantage of the instant large-capacity charging of supercapacitors but also takes advantage of the specific energy advantages of lead-acid batteries.

Lead carbon battery is a mixture of asymmetric supercapacitors and lead-acid batteries using the internal parallel connection. As a new type of super battery, a lead-carbon battery is a combination of lead-acid batteries and supercapacitors, which is also a kind of dual-function energy storage battery with both capacitive and battery characteristics. Therefore, it not only takes advantage of the instant power and large capacity charging of supercapacitors but also takes advantage of the energy advantages of lead-acid batteries, which can be fully charged in one hour and has a good charge and discharge performance. Due to the use of lead-carbon battery technology, the performance of the lead-carbon battery is far superior to traditional lead-acid batteries, so the lead-carbon battery can be used in new energy vehicles, such as hybrid vehicles, electric bicycles, and other fields; it can also be used in the field of new energy storage, such as wind power generation and energy storage.

Battery technology is the key to restricting the development of the energy storage industry. Lead-acid batteries are an ancient and practical battery technology. The new generation of lead-carbon batteries produced by the optimization of the introduction of capacitive carbon has become an important help for this magical battery technology to continue the legend in the new era. With the advantages of strong charge acceptance, safety and reliability, and low manufacturing cost, under the background of the widespread use of renewable energy and the continuous expansion of the energy storage market, lead-carbon batteries will become another development direction of energy storage batteries after lithium-ion batteries and flow batteries.

HOW TO STORE LEAD CARBON BATTERIES?

The proper storage of your lead carbon batteries is critical to extending their life. When storing a lead carbon battery, two aspects must be taken into account: temperature and storage period. Here’s what you should know:

- Recommended storage temperature: 15 – 20 °C (59 – 68 °F)

- Allowable Temperature Range: -20 to 50 °C (-4 to 122 °F)

The table below shows the discharge percentage after 6 months of storing our lead carbon batteries at different temperatures:

| Temperature | From Full Charge |

|---|---|

| 0°C | 98% |

| 25°C | 93% |

| 40°C | 69% |

| 60°C | 43% |

STORAGE RECOMMENDATIONS FOR A LEAD CARBON BATTERY:

- Charge the battery fully before storing.

- Store the battery at or below room temperature.

- Do not leave the battery in its application during storage.

- Charge it up every six months

- Do not allow the battery to deeply discharge.

- Set the correct float voltage to avoid sulfation & corrosion.

SIGNS OF IMPROPER LEAD CARBON STORAGE:

- The battery terminals are corroded and the battery looks to be in bad shape.

- The lights are flickering or dim during battery use.

- The equipment or application is not responding to user actions.

- The battery is dead and does not read a voltage.

Faqs

Here are some common questions we’ve been asked. You may find answers to more complicated questions in the Technical pages.

What is the difference between lead-carbon batteries and ordinary lead-acid batteries?

Lead-carbon batteries have been developed from traditional lead-acid batteries to provide better deep cycling ability and reduce sulphation of the negative plates when used in partial states of charge. The first lead-carbon batteries were developed by the CSIRO (Govt. scientific research facility) in Australia in the mid-2000’s and commercialised around 10 years ago, first known as the “Ultra battery” and subsequently developed further by several lead battery manufacturers. Brava have been producing the Brava series of lead-carbon batteries since 2013. See the Technical section on this website for a detailed explanation of lead carbon technology.

The negative plate of a lead-carbon battery contains carbon. Different techniques are used by different lead-carbon battery manufactures to create this mix of lead and carbon on the negative plate. Some wrap the negative plate in a carbon film, others mix the lead and carbon in a matriculates, and others use proprietary nano-carbon particles.

The use of highly conductive carbon on the negative plate gives the lead-carbon battery the characteristics of a “super capacitor” that can more rapidly absorb charge current, and more rapidly deliver current under load than traditional lead-acid batteries. This means they can be recharged faster and can deliver higher peak load currents without damage compared to other lead-acid battery types.

How long will a Brava lead-carbon battery bank last?

There are a few key factors that will determine how long your battery bank will last. These are

- how deeply you regularly discharge the batteries (“depth of discharge” or DoD)

- whether you have a stable temperature environment

- if you can get them fully recharged regularly

If you discharge the batteries on average to 50% DoD once a day, have them inside in a stable temperature that ranges from 15 to 25 °C, and have enough solar panels to recharge them completely when you get a full sunny day, then you can expect 10 to 12 years life. If you discharge less than this you can get a lifetime of 15 years or more. On our Technical page there is a chart of cycle life vs depth of discharge which gives you an idea of how many times you can cycle the batteries for a given DoD. Lead carbon batteries have cycle counts for a given DoD that are 3 or 5 times that of typical flooded lead-acid batters or GEL/AGM batteries.

High temperatures are a problem for all battery types. Ambient temperatures over 30 °C will cause corrosion of the positive battery plate internally and can lead to battery failure within a few years. If your battery bank is kept in an outside shed ensure the building is not subject to direct hot summer sun that could heat it up internally.

Although lead-carbon batteries can handle being used in a partial state of charge for extended periods, they do need to be fully charged from time to time to keep their full operating capacity. Over winter it is very easy to end up with your battery bank in a permanent state of 50% discharge or worse. You need to fully charge the batteries at least once per month. This can be achieved with a generator, or more economically these days by having more solar panels than you think you might need, so that in winter you can generate enough current to fully charge batteries on a sunny day. You may end up with excess solar capacity in summer, but most modern controllers can simply ignore this excess capacity without causing harm – but do check your own controllers specifications.

Can I replace my old flooded lead-acid or GEL/AGM battery bank with lead-carbons?

In most cases the answer is yes. As long as your solar charger settings can be changed to the slightly lower settings needed for lead-carbon batteries then they can easily replace your old battery bank. You will have the bonus of more usable energy in the new battery bank because you can discharge the lead-carbon batteries more deeply without damage compared to traditional lead-acid batteries. Most older lead-acid battery manufactures recommend that their batteries be discharged by no more than 30% to achieve a useful life of 5 years. The same size lead-carbon battery bank can be discharged to 50% and achieve a useful life of 10 years plus.

Do lead-carbon batteries need regular maintenance?

Brava lead-carbon batteries are sealed valve-regulated lead-acid (VRLA) type batteries. This means the electrolyte that moves energy between the positive and negative battery plates does not need “topping up” with water as with flood battery types. It is held between the plates in a thick gel paste and the battery itself is sealed apart from a safety valve which only releases gas if the battery overheats or is seriously overcharged. Brava lead-carbons can be mounted in any orientation – on their side or upside down, and have the added advantage that they can be transported easily and safely as they are not classed as dangerous goods.

Are they safe to have inside? What about gases being given off?

In normal daily use no gas is given off from the Brava series batteries. They do not give off flammable hydrogen gas like flooded lead-acid batteries unless they are severely overcharged, overheated or damaged. They can be safely used inside a building, and this also helps keep them at the optimum operating temperature of 15 to 25 degrees C. There is a New Zealand standard – AS/NZS 5139 – that gives details on how to install a battery bank inside a building. This includes not installing in a habitable room such as a living room or bedroom. Installation in a garage, utility room or laundry is fine as long as the guidelines are followed. See the Technical section on Installation for more details.

What is the warranty on Brava lead-carbon batteries

All batteries are unconditionally warranted to meet their full performance specification for a period of 12 months. In the event that they do not, the faulty battery will be replaced.

Batteries that are operated with an average DoD of 65%, with no more than 1 cycle per day, and kept at a temperature of 15 to 25 °C will be warranted for a period of 5 years from date of purchase to meet 80% of their original capacity specification. In the event that they do not, a credit calculated at a pro-rata rate from years 1 to 5 will be given towards the replacement cost, or an equivalent refund of the original purchase price will be given.

The warranty from Coromandel Batteries is backed by the Brava factory warranty, issued specifically to our company for the entire range of Brava series batteries. This can be viewed in the document here.

How do the different Ah capacity ratings work – C10, C100 etc?

Different battery manufacturers rate their batteries in different ways, but usually the capacity is given in amp-hours (Ah) over a certain time of discharge. The C10 Ah rating means the capacity when the battery is fully discharged over a period of 10 hours. The C100 Ah rating means the battery is discharged fully over 100 hours. Due to the nature of the chemical reactions in a battery, a slower discharge will allow the battery to give more energy than a fast discharge. So C100 or C120 ratings are always higher than C10 or C20 ratings. A C100 rating is generally more applicable to solar setups since batteries for off-grid use are not usually discharged in 10 or 20 hours, but more likely over 2 to 4 days if the weather is cloudy. So the C100 or C120 rating is generally a good indication of battery capacity. But remember that most batteries are not designed to be 100% discharged, so the useful capacity is less than the total capacity. Brava lead-carbon batteries are designed to be discharged more deeply than other lead-acid types, and a warranted for 5 years at a 65% depth of discharge. See here for more information on depth of discharge (DoD).

How efficient are lead-carbon batteries at converting solar energy to stored energy?

One way to measure battery efficiency is to measure how much energy has to go back into a battery during charging to make up for the energy used during discharge. Figures given by Trojan, a major battery manufacturer of all battery types, say flooded lead-acids need 107 to 120% as much energy to recharge as they produce during discharge. GEL/AGM type batteries (which include Brava lead-carbon) are somewhat more efficient with 105 to 109%. Lithium ion are 105 to 115%. There is quite a range in these efficiencies because the efficiency changes depending on the state of charge. A battery at a 50% state of charge has a higher efficiency than one that is nearly fully charged. So over 95% of the energy coming from your solar panels will get into your batteries when they are half charged, but as they get to 90% full the efficiency will drop to nearer 80% and even less as the last bit of energy is squeezed into the batteries. Because Narada lead-carbon batteries can operate at partial states of charge without sulphating to the extent that flooded or other AGM batteries do, they can generally be operated with higher conversion efficiencies than other battery types, resulting in less wasted energy. Remember that there are other inefficiencies in your system also – such as the inverter. The inverter will waste between 5 and 15% of the energy it takes from your batteries at low voltage (48, 24 or 12V DC) to convert mains voltage (240V AC). So when you combine battery efficiency and inverter efficiency you can easily be losing 20% of your solar power compared to usable mains power at the 240V socket.

BRAVA is one of the leading lead carbon battery manufacturers & suppliers in China, please contact us! 12v lead carbon battery available!